Choosing the Right Aluminium Alloy Shim: Grades 6063, 6082, 6083, 7050 & 7075 Explained

Pipex.ai supplies a wide range of industrial metal products, and aluminium alloy shims remain one of the most essential components for achieving precise alignment, load balancing, and long-term mechanical stability across multiple industries.

Gönderildi 8 saatler önce içinde diğer, güncellenmiş 8 saatler önce.

1. Choosing the Right Aluminium Alloy Shim: Grades 6063, 6082, 6083, 7050 & 7075 Explained

Pipex.ai supplies a wide range of industrial metal products, and aluminium alloy shims remain one of the most essential components for achieving precise alignment, load balancing, and long-term mechanical stability across multiple industries.

Introduction: Why Aluminium Alloy Shims Are Critical in Industrial Installations

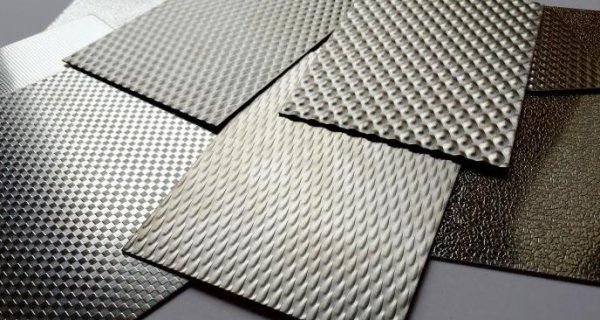

In industrial and structural assemblies, even a minor gap or uneven surface can cause serious problems such as vibration, stress concentration, equipment misalignment, and early component failure. Aluminium alloy shims are thin metal sheets used to fill these gaps and maintain correct positioning between machine bases, frames, and structural joints.

From a buyer’s perspective, aluminium alloy shims offer several practical advantages:

Lightweight handling during installation

Good corrosion resistance

Reliable mechanical performance

Availability in multiple thickness ranges

Cost efficiency compared to heavier metals

However, not all aluminium alloys perform the same. Selecting the right grade directly affects load capacity, durability, and long-term performance.

What Buyers Should Evaluate Before Selecting Shim Grades

Before choosing a specific alloy, procurement teams and engineers typically assess the following factors:

Load Requirements

Higher load conditions demand stronger alloys that can resist compression and deformation over time.

Environmental Exposure

Outdoor, marine, or chemical environments require alloys with better corrosion resistance.

Installation and Machining Needs

Some projects require shims to be trimmed, drilled, or stacked on-site, so formability and machinability become important.

Maintenance and Lifecycle Costs

Cheaper alloys may reduce initial cost but increase maintenance frequency and downtime.

Understanding these requirements helps buyers select the most suitable aluminium alloy shim grade for each project.

Aluminium Alloys Shim 6063: Best for Light-Duty and General Alignment

Aluminium alloys shim 6063 is commonly used where moderate strength and excellent surface finish are required.

Typical Buyer Applications

Electrical panels and enclosures

Light machinery bases

Architectural fittings

Equipment casing alignment

Buyer Benefits

Good corrosion resistance

Easy to cut and shape

Smooth surface for better contact

Cost-effective for bulk purchases

This grade is preferred when structural load is low and ease of handling during installation is important.

Aluminium Alloys Shim 6082: Strong and Reliable for Industrial Use

Aluminium alloys shim 6082 is a higher-strength alloy widely used in industrial and structural applications.

Typical Buyer Applications

Heavy machinery installation

Structural steel leveling

Industrial support frames

Conveyor systems

Buyer Benefits

High mechanical strength

Good resistance to environmental exposure

Suitable for medium to heavy loads

Good machinability

Buyers choose this grade when performance requirements are higher, but aerospace-level strength is not necessary.

Aluminium Alloys Shim 6083: Built for Tough Structural Conditions

Aluminium alloys shim 6083 is designed for demanding environments where structural stability and resistance to deformation are critical.

Typical Buyer Applications

Infrastructure projects

Transport equipment

Heavy-duty mechanical platforms

Marine structural supports

Buyer Benefits

High resistance to bending and compression

Stable performance under continuous load

Suitable for harsh operating environments

This grade is often selected by buyers when long-term reliability and structural safety are key priorities.

Aluminium Alloys Shim 7050: High Strength for Critical Load Applications

Aluminium alloys shim 7050 is known for its superior strength and resistance to stress-related cracking, making it suitable for highly demanding conditions.

Typical Buyer Applications

Precision machinery foundations

Aerospace tooling

High-load structural assemblies

Critical industrial equipment

Buyer Benefits

Excellent tensile strength

Strong fatigue resistance

Better performance under cyclic loads

Longer service life under stress

Buyers opt for this grade when safety margins must be higher and operational downtime is extremely costly.

Aluminium Alloys Shim 7075: Maximum Strength for Extreme Environments

Aluminium alloys shim 7075 is among the strongest aluminium alloys available, often compared to mild steel in terms of strength while remaining much lighter.

Typical Buyer Applications

Heavy industrial machinery

Defense and aerospace systems

High-impact equipment installations

Specialized engineering assemblies

Buyer Benefits

Exceptional strength-to-weight ratio

High fatigue resistance

Suitable for extreme stress conditions

Although more expensive, buyers justify the investment where performance failure is not an option.

Thickness and Tolerance: Why Precision Matters to Buyers

Beyond alloy selection, thickness consistency is critical for accurate alignment.

Thickness Options

Aluminium alloy shims are supplied in a wide range of thicknesses, from very thin sheets to several millimeters. Buyers often stack multiple shims to achieve precise adjustments.

Dimensional Accuracy

Uniform thickness across the entire sheet prevents uneven load distribution, which can otherwise lead to vibration and structural damage.

Surface Quality

Smooth, burr-free surfaces improve contact between components and reduce micro-movement over time.

Buyers should always ensure that shims meet industry tolerances and are manufactured under controlled quality standards.

Cost Considerations: Balancing Budget and Performance

From a procurement standpoint, aluminium alloy shim selection involves balancing upfront cost with long-term operational savings.

Lower-grade alloys may:

Cost less initially

Require more frequent maintenance

Deform faster under load

Higher-grade alloys may:

Increase initial material cost

Reduce downtime

Improve equipment lifespan

Experienced buyers evaluate total ownership cost rather than just product pricing, especially for heavy machinery and infrastructure projects.

Industries That Rely on Aluminium Alloy Shims

Aluminium alloy shims are widely used across multiple sectors, including:

Power generation plants

Oil and gas facilities

Automotive manufacturing

Construction and steel fabrication

Marine and offshore installations

Heavy engineering workshops

Each industry has different performance demands, making grade selection an essential part of procurement planning.

Quality Documentation and Compliance: Important for Professional Buyers

For large projects, buyers often require:

Material test certificates

Compliance with ASTM or EN standards

Batch traceability for future reference

These documents support safety audits, project approvals, and long-term maintenance strategies, making supplier reliability just as important as material quality.

Conclusion: Smart Grade Selection Ensures Long-Term Performance

Choosing the right aluminium alloy shim is a critical decision that affects alignment accuracy, load stability, and overall system reliability. While aluminium alloys shim 6063 is suitable for light-duty applications, grades such as aluminium alloys shim 6082 and 6083 serve industrial and structural needs, and high-strength options like aluminium alloys shim 7050 and aluminium alloys shim 7075 are designed for extreme load and critical engineering conditions.