High-Integrity Round Bars for Aerospace and Heavy Engineering - Neptune Alloys

Round bars play a crucial role in modern industrial manufacturing, offering strength, precision, and versatility across applications. With advanced alloy grades and strict quality control, they meet the evolving demands of high-performance industries. Choosing a reliable supplier ensures consistency, safety, and long-term value, making round bars a dependable foundation for critical engineering projects.

Posted 2 months ago in other, updated 2 months ago.

1. High-Integrity Round Bars for Aerospace and Heavy Engineering - Neptune Alloys

Neptune Alloys is a trusted name in the metal industry, known for supplying high-quality round bars engineered for demanding industrial environments. As a reliable Round Bar Supplier in India, the company focuses on delivering products that combine mechanical strength, dimensional accuracy, and long service life. Round bars are widely used across sectors such as aerospace, automotive, power generation, and heavy engineering due to their versatility and consistent performance.

Understanding the Importance of Round Bars

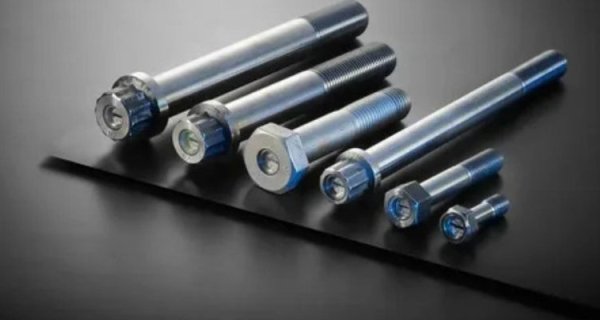

A round bar is a solid cylindrical metal product commonly used in machining, fabrication, and structural applications. Its uniform cross-section makes it ideal for components that require strength, balance, and precision. From shafts and fasteners to gears and high-stress mechanical parts, round bars form the backbone of countless industrial assemblies. Choosing the right grade and size is essential to ensure safety, durability, and efficiency in operation.

Specialized Grades for High-Performance Applications

Modern industries demand materials that can withstand extreme conditions such as high temperatures, pressure, and corrosion. For such applications, alloy-based round bars are often preferred. Some of the most widely used high-performance grades include:

A286 - AMS 5737 Round Bar

This grade is known for excellent strength at elevated temperatures, making it suitable for aerospace and gas turbine components where thermal stability is critical.

A286 - AMS 5731 Round Bar

Designed for high-stress environments, this grade offers good corrosion resistance along with reliable mechanical properties, ideal for structural and fastening applications.

A286 - AMS 5732 Round Bar

Often used in demanding engineering systems, this grade provides a balance of strength, toughness, and resistance to oxidation at higher temperatures.

A286 - AMS 5525 Round Bar

This grade is commonly used in precision components that require consistency, machinability, and long-term reliability under cyclic loads.

Each of these grades is manufactured to meet strict international standards, ensuring dependable performance in critical applications.

Manufacturing Quality and Material Control

Round bars are produced through controlled processes such as hot rolling, forging, and precision finishing. Attention is given to chemical composition, grain structure, and surface quality to ensure uniformity across the length of the bar. Proper heat treatment further enhances mechanical properties, allowing the material to perform reliably under load and stress. A dependable Round Bar Supplier ensures that every product undergoes dimensional checks and quality inspections before dispatch.

Applications Across Major Industries

Round bars are essential in a wide range of industries:

- Aerospace: Used for engine components, fasteners, and structural parts that operate under high temperatures and stress.

- Automotive: Ideal for shafts, axles, and transmission components requiring strength and fatigue resistance.

- Power & Energy: Applied in turbines, boilers, and high-pressure systems where material reliability is critical.

- Heavy Engineering: Used in machinery parts, couplings, and custom-fabricated components.

Their adaptability makes round bars a preferred choice for both standard and customized engineering solutions.

Selecting the Right Size and Weight

Accurate selection of diameter and length is vital for performance and cost efficiency. Engineers often refer to the Round Bar Weight Chart to calculate material weight based on dimensions, helping in load calculations, transportation planning, and overall project budgeting. Proper selection reduces material waste and ensures optimal structural performance.

Conclusion

Round bars play a crucial role in modern industrial manufacturing, offering strength, precision, and versatility across applications. With advanced alloy grades and strict quality control, they meet the evolving demands of high-performance industries. Choosing a reliable supplier ensures consistency, safety, and long-term value, making round bars a dependable foundation for critical engineering projects.