High-Quality Nuts Manufacturers in India for Industrial and Construction Needs

Sachiya Steel International is one of the high-quality Nuts Manufacturers in India has emerged as a global hub for high-quality industrial fasteners, and among them, nuts play a critical role in ensuring the strength and stability of structures and machinery.

Gesendet 2 Monate vor im andere, aktualisiert 2 Monate vor.

1. High-Quality Nuts Manufacturers in India for Industrial and Construction Needs

Sachiya Steel International is one of the high-quality Nuts Manufacturers in India has emerged as a global hub for high-quality industrial fasteners, and among them, nuts play a critical role in ensuring the strength and stability of structures and machinery. Nuts Manufacturersare recognized for their ability to produce a wide range of precision-engineered nuts that meet both domestic and international standards. These manufacturers cater to industries such as construction, automotive, oil and gas, railways, shipbuilding, and power generation, making them an integral part of the supply chain for various sectors.

Wide Range of Products

Nuts suppliers produce different types of nuts to meet diverse application requirements. Common types include:

Heavy Hex Nuts – Widely used in construction and machinery.

Lock Nuts – Designed to prevent loosening under vibration.

Flange Nuts – Offering a larger bearing surface for better load distribution.

Wing Nuts – Easy to install and remove without tools.

Square Nuts – Known for their strength and classic design.

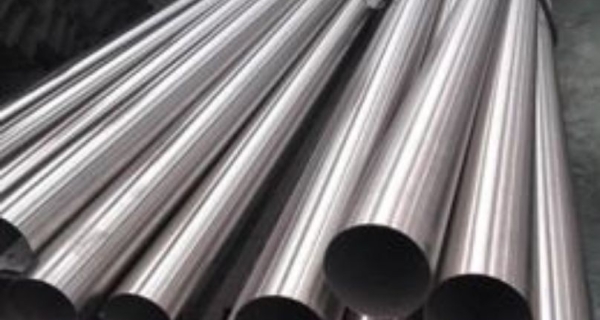

Manufacturers offer these nuts in various materials such as stainless steel, carbon steel, brass, and alloy steel, with coatings like zinc plating, galvanizing, or black oxide to enhance durability and corrosion resistance.

Quality Standards and Certifications

One of the key reasons for the success of nuts manufacturers in India is their commitment to quality. Reputed manufacturers follow strict quality control measures at every stage of production, from raw material inspection to final dispatch. Many are certified with ISO 9001, ISO 14001, and other industry-specific certifications, ensuring products meet the highest standards of performance and reliability. Non-destructive testing, torque tests, and dimensional accuracy checks are standard practices to ensure each nut performs flawlessly in its application.

Technological Advancements

Nuts Manufacturers have embraced modern manufacturing technologies, including:

CNC machining for precision shaping.

Cold and hot forging techniques to ensure structural integrity.

Automated threading machines for consistency and speed.

Advanced heat treatment processes to improve strength and hardness.

These technological upgrades allow manufacturers to produce nuts in bulk quantities without compromising quality, enabling them to meet tight deadlines for large-scale projects.

Competitive Advantages of Indian Manufacturers

India’s nuts manufacturing industry stands out globally due to several factors:

Cost Efficiency – Lower production costs without compromising on quality.

Skilled Workforce – Highly trained engineers and technicians with deep industry knowledge.

Customization Capability – Ability to produce nuts in custom sizes, designs, and materials as per client specifications.

Global Supply Chain Integration – Many manufacturers have robust export capabilities, serving clients in the USA, Europe, the Middle East, Africa, and Southeast Asia.

Applications Across Industries

Nuts manufactured in India find applications in:

Construction – For securing steel structures, beams, and frames.

Automotive Industry – Used in engines, chassis, and assembly lines.

Oil and Gas – High-strength nuts for offshore and onshore rigs.

Renewable Energy – Securing wind turbines and solar panel frames.

Railways and Shipbuilding – Heavy-duty nuts designed to withstand harsh environments.

Sustainability and Future Outlook

With growing global emphasis on sustainability, many Indian nuts manufacturers are adopting eco-friendly production methods. This includes recycling scrap metal, reducing energy consumption, and implementing waste management systems. Additionally, the increasing demand for infrastructure development, electric vehicles, and renewable energy projects is expected to boost the nuts manufacturing sector in India over the coming years.

Nuts Suppliers in India have built a strong reputation for delivering high-quality, reliable, and cost-effective fastening solutions to industries worldwide. Through advanced technology, stringent quality control, and a focus on innovation, these manufacturers continue to strengthen India’s position as a trusted global source for industrial nuts. Whether for large-scale infrastructure projects or specialized engineering applications, the expertise and capabilities of Indian manufacturers make them a preferred choice for clients across the globe.