Weld Neck Flanges Applications And uses

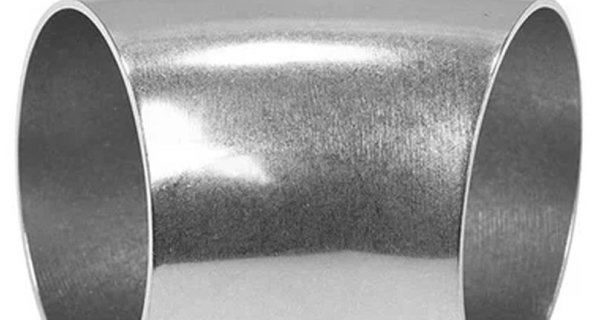

Nitech Stainless Inc produces stainless steel Weld Neck flanges that meet ASME, EN, ISO, and DIN specifications. Stainless steel is a durable material. Flanges around the weld neck Buttwelding will be used to link this to a piping device.

Gesendet 5 Jahre vor im andere, aktualisiert 5 Jahre vor.

1. Weld Neck Flanges Applications And uses

Nitech Stainless Inc produces stainless steel Weld Neck flanges that meet ASME, EN, ISO, and DIN specifications. Stainless steel is a durable material. Flanges around the weld neck Buttwelding will be used to link this to a piping device. Because of its collar, it is relatively exclusive, but it is preferred for high-stress applications. The neck or hub transfers stress from the hub’s base to the wall width at the butt weld, providing significant flange reinforcement. The Stainless Steel Weld Neck Flanges has a bore that suits the pipe’s bore, eliminating turbulence and erosion.

Weld Neck Flanges Applications

A weld neck flange is a circular fitting with a protruding rim around the circumference that connects to a pipe with a welding neck. With strong sealing, weld neck flanges are difficult to deform. It works well with high-temperature, high-pressure, and low-temperature pipes, as well as pipes with varying pressure and temperature. The nominal pressure, in this case, is no more than 2.5 MPa, and the advantage is that the price is lower; weld neck flanges are often used for pipelines that carry flammable and explosive medium with high shipping costs. The nominal pressure is about 16MPa under these conditions. The weld neck flange link is easy and can withstand more strain. The content of the weld neck flange gasket can vary depending on the pressure level, varying from low-pressure asbestos gasket to high-pressure asbestos gasket to metal gasket.

1. Artifact extension: strip steel, profile steel, wire rod, reinforcing steel, boiler steel pipe, oil and gas pipe butt welding

2. Ring artifact butt welding: butt welding of car rims, bicycle rims, motorcycle rims, and other chainrings.

3. Welding simple rolling, forging, stamping, or machined parts together to make complicated parts will save money. Butt welding of the car direction shaft housing and rear axle shell, butt welding of various connecting rods and draw rods, butt welding of special sections, and so on.

4. Dissimilar metal butt welding can help save precious metals while also improving production efficiency. Such as the butt welding of the cutter’s work component (HSS) and tail (medium carbon steel), the butt welding of the head (heat resistant steel) and tail (constructional steel) of internal combustion engine exhaust valves, the butt welding of aluminium copper conductive couplings, and so on.

The application of a weld neck flange must be calculated based on the situation, ensuring the particular usage value and efficiency, as well as the ability to withstand high temperatures and pressure. The weld neck flange is designed for steel pipe connections with a maximum nominal pressure of 2.5 MPa.

Read full article - weld neck flanges applications and uses

Source - weld neck flanges manufacturers