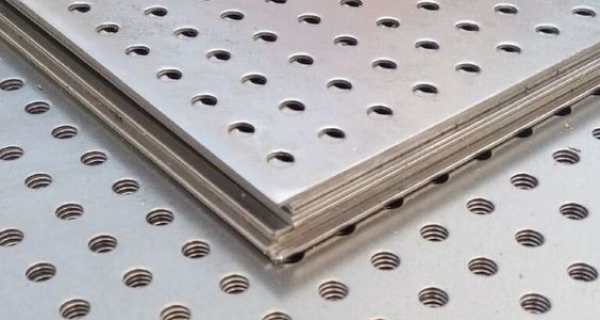

Exploring the Different Grades of Round Bars- Neptune Alloys

Neptune Alloys stand-out as one of the best Round Bar Manufacturer in India

Gesendet 4 Monate vor im Technologie, aktualisiert 4 Monate vor.

Exploring the Different Grades of Round Bars- Neptune Alloys

Neptune Alloys stand-out as one of the best Round Bar Manufacturer in India, renowned for delivering high-quality round bars crafted from premium materials such as stainless steel, Inconel, Hastelloy, Alloy 20, Monel, and more. Our round bars are manufactured to meet global standards and are available in various grades, sizes, and finishes to suit the needs of industries such as aerospace, power generation, oil & gas, petrochemical, and marine engineering. With state-of-the-art facilities and strict quality control, Neptune Alloys ensures each round bar offers superior strength, corrosion resistance, and durability.

As a trusted Round Bar Manufacturer in India, we maintain a ready inventory to fulfill bulk and urgent orders with timely delivery across domestic and international markets. Our commitment to precision manufacturing and customer satisfaction sets us apart in the metal industry. Whether for structural applications, fastener production or custom-engineered solutions, Neptune Alloys provides reliable and cost-effective round bar solutions tailored to your project requirements.

Grades of Round Bars Offered by Neptune Alloys

Below are the top-grade round bars that we offer, each known for their unique properties and specific industry applications:

Inconel X750 is a nickel-chromium alloy made to withstand high-stress conditions at elevated temperatures. This round bar is widely used in jet engines, gas turbines, and nuclear reactors.

Key Features:

- High tensile and creep-rupture strength

- Excellent resistance to oxidation and corrosion

- Long-term performance at temperatures up to 1300°F (700°C)

Applications: Aerospace engines, heat exchangers, pressure vessels, and nuclear components

ASTM A453 Grade 660 Class A Round Bar

Grade 660 Class A is a high-strength alloy made of iron, nickel, and chromium, offering superior oxidation and corrosion resistance.

Key Features:

- Maintains mechanical properties at elevated temperatures

- Good weldability and machinability

- Resistant to thermal fatigue

Applications: High-temperature bolting, turbines, pressure vessels

ASTM A453 Grade 660 Class B Round Bar

This class offers improved tensile strength and thermal resistance, making it suitable for critical fasteners and bolting solutions.

Key Features:

- Better stress-rupture performance

- High oxidation resistance

- Ideal for use in harsh environments

Applications: Chemical plants, thermal power plants, steam lines, and flanges

ASTM A453 Grade 660 Class C Round Bar

Known for its balance between strength and ductility, Class C is often used where components are subjected to repeated temperature fluctuations.

Key Features:

- Exceptional long-term creep resistance

- Enhanced mechanical strength

- Sustains in oxidizing conditions

Applications: Pressure vessels, oil refineries, and boiler manufacturing

ASTM A453 Grade 660 Class D Round Bar

Grade 660 Class D is ideal for extremely high-temperature environments requiring consistent strength and oxidation resistance.

Key Features:

- Highest creep rupture strength among all 660 grades

- Durable under thermal cycling

- Suitable for elevated service environments

Applications: Aerospace structures, industrial turbines, furnace hardware

Alloy A286 is a high-performance austenitic iron-based alloy that exhibits outstanding tensile strength and oxidation resistance at high temperatures.

Key Features:

- Maintains integrity in environments up to 1300°F

- Corrosion-resistant in salt water and industrial chemicals

- Easy to weld and fabricate

Applications: Aerospace, automotive turbochargers, superchargers, and afterburners

Hastelloy X is a nickel-based alloy designed for high-temperature strength and excellent oxidation resistance.

Key Features:

- Outstanding resistance to stress corrosion cracking

- Works well in oxidizing and reducing atmospheres

- Withstands prolonged exposure to high temperatures

Applications: Aircraft engine parts, petrochemical processing, heat exchangers

Why Choose Neptune Alloys as Your Round Bar Supplier?

Neptune Alloys stands apart in the Indian metal industry as a trusted round bar supplier for several reasons:

- Premium Quality Assurance

All products are manufactured using the finest raw materials and follow ISO-certified processes for consistent quality.

- Wide Inventory of Grades

Whether it's Inconel, Hastelloy, Alloy A286, or ASTM A453 Grade 660, we maintain a large ready stock to fulfill urgent bulk orders.

- Customization

Need round bars in specific diameters, lengths, or tolerances? We provide tailored solutions to meet your project's exact requirements.

- Competitive Pricing

Get the best value without compromising on quality. Our prices are designed to be competitive in both domestic and global markets.

Conclusion

When it comes to sourcing high-performance round bars for demanding applications, Neptune Alloys is the name you can trust. As a premier round bar supplier in India, we combine material excellence with engineering precision to deliver bars that exceed performance expectations. From Inconel X750 to ASTM A453 Grade 660 and Hastelloy X, every round bar we supply ensures strength, durability, and long service life.

Explore our full range at: neptunealloys.com

For specific product details: Round Bar Supplier in India