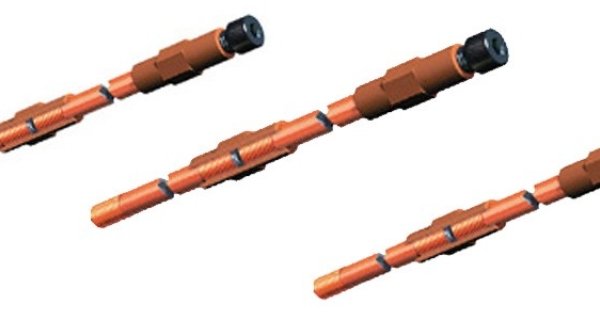

Round Bar's Journey: From Raw Material to Finished Goods - ShashwatStainless

Shashwat Stainless Inc. is the best Round Bars Manufacturer in India. Round bars are vital parts of several sectors, including manufacturing and construction. Have you ever wondered what goes into making these cylindrical bars? Let's take a tour around the round bar production process.

Posted 2 years ago in International, updated 2 years ago.

Shashwat Stainless Inc. is the best Round Bars Manufacturer in India. Round bars are vital parts of several sectors, including manufacturing and construction. Have you ever wondered what goes into making these cylindrical bars? Let's take a tour around the round bar production process.

Round Bar Manufacturing Process

Raw Material Selection:

The process starts with the choice of premium raw materials. Brass, aluminum, and steel are the most frequent metals used to make round bars. The selected material needs to have the necessary qualities, like resilience to corrosion, strength, and durability.

Melting and Casting:

After being chosen, the raw material goes through a procedure known as melting. The material is heated in a furnace to its melting point in this step. Once melted, it is poured into precisely shaped and sized molds. The round bar takes on its original shape through this casting process.

Rolling Mill:

The semi-finished round bars are transferred to the rolling machine after casting. Here, they go through a number of rolling procedures to get the correct size and level of surface finish. The circular bars are fed through a sequence of rollers that lengthen them and progressively decrease their diameter.

Hot Rolling:

An important stage in the production process is hot rolling. To increase their malleability, the semi-finished round bars are heated to high temperatures. This facilitates the metal's shaping into the appropriate diameter by the rollers. Additionally, hot rolling strengthens and toughens the round bars' mechanical characteristics.

Cold Drawing:

The round bars may go through a procedure called cold drawing after being heat rolled. The hot-rolled bars are drawn through a sequence of room-temperature dies in this process. By doing this, the diameter is further decreased and the bars' surface polish is enhanced. The circular bars are further given homogeneity by cold drawing, which guarantees constant dimensions along their whole length.

Annealing:

The heat treatment procedure known as annealing is used to reduce internal tensions and increase the round bars' ductility. The bars are heated to a certain temperature and then gradually cooled following cold drawing. The round bars' desired mechanical qualities and machinability are achieved with the aid of this procedure.

Straightening and Cutting:

The circular bars may be straightened when annealing is finished to make sure there are no bends or twists in them. Any distortions in the bars are fixed with the help of straightening equipment. The spherical bars are straightened and then sawed or sheared to the desired length.

Surface Treatment:

To improve the round bars' look and ability to withstand corrosion, surface treatment is frequently applied. This could entail procedures like grinding, polishing, or painting or plating the bars to provide protection.

Quality Control:

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the round bars meet the required specifications and standards. This involves conducting various tests such as dimensional inspection, mechanical testing, and surface analysis.

Packaging and Shipping:

Once the round bars pass the quality control checks, they are ready for packaging and shipping. The bars are carefully packed to prevent any damage during transportation and storage. They are then shipped to customers or distributors to be used in various applications.

High Grade Round Bar Manufacturer in India - ShashwatStainless

Shashwat Stainless Inc. is the best Round Bar Suppliers in India. We are an ISO 9001:2008 certified firm. Established in 2007, Shashwat Stainless Inc. is headed by a team of very proficient technical experts that possess vast experience in producing flanges, buttweld fittings, forged fittings, and duplex and super duplex steel.

Shashwat Stainless Inc. is a burgeoning enterprise based in India that manufactures and distributes premium stainless steel, alloy steel, carbon steel, pipe and tube fittings, forged fittings, and numerous other goods.

Conclusion

In summary, there are a number of complex procedures involved in the production of round bars, from the selection of raw materials to the last inspection and packing. In order to produce high-quality round bars that satisfy the various demands of industries worldwide, each step is vital.